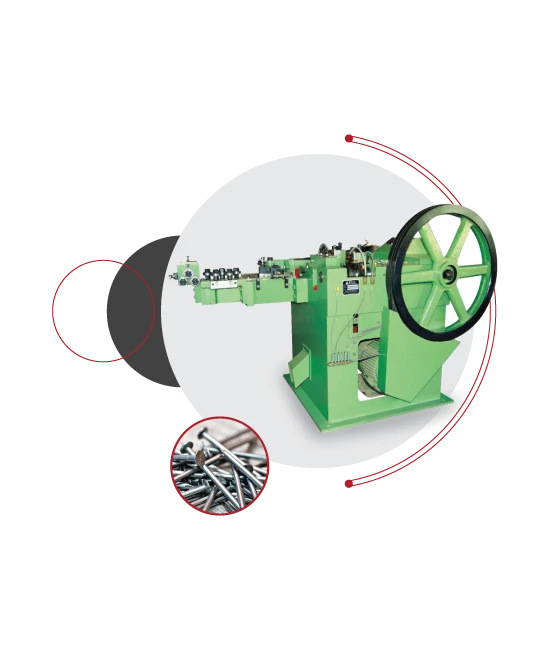

When it comes to manufacturing wire nails, precision and efficiency are key. Top-quality wire nail making equipment plays a crucial role in producing consistent, high-strength nails used across construction, carpentry, packaging, and other industries. These machines are engineered with advanced technology and built using high-grade materials to deliver flawless performance over years of operation.

Precision engineering ensures that every component of the wire nail machine works in perfect harmony. From the wire feeding system to the cutting and shaping mechanisms, each part is calibrated to maintain uniform nail length, thickness, and head shape. This not only improves the visual and structural quality of the nails but also minimizes material waste and production errors, which is essential in bulk manufacturing.

Top manufacturers of wire nail equipment focus on durability, automation, and user-friendly operation. Their machines come equipped with automatic lubrication systems, hardened die parts, and heavy-duty construction to support continuous production. Whether producing thin panel pins or heavy-duty construction nails, these machines can be adjusted easily to accommodate various specifications.

Exporters of precision-engineered nail machines are increasingly catering to global markets, offering tailor-made solutions and round-the-clock support. Their equipment is trusted by industries worldwide for delivering high productivity, low maintenance costs, and long-term reliability. If you're in the nail manufacturing business and looking to scale up with dependable machinery, investing in top-quality wire nail making equipment is a smart and future-proof decision.